- sales@biolabmarket.com

- +1 (469) 819-5592

vacuum pump

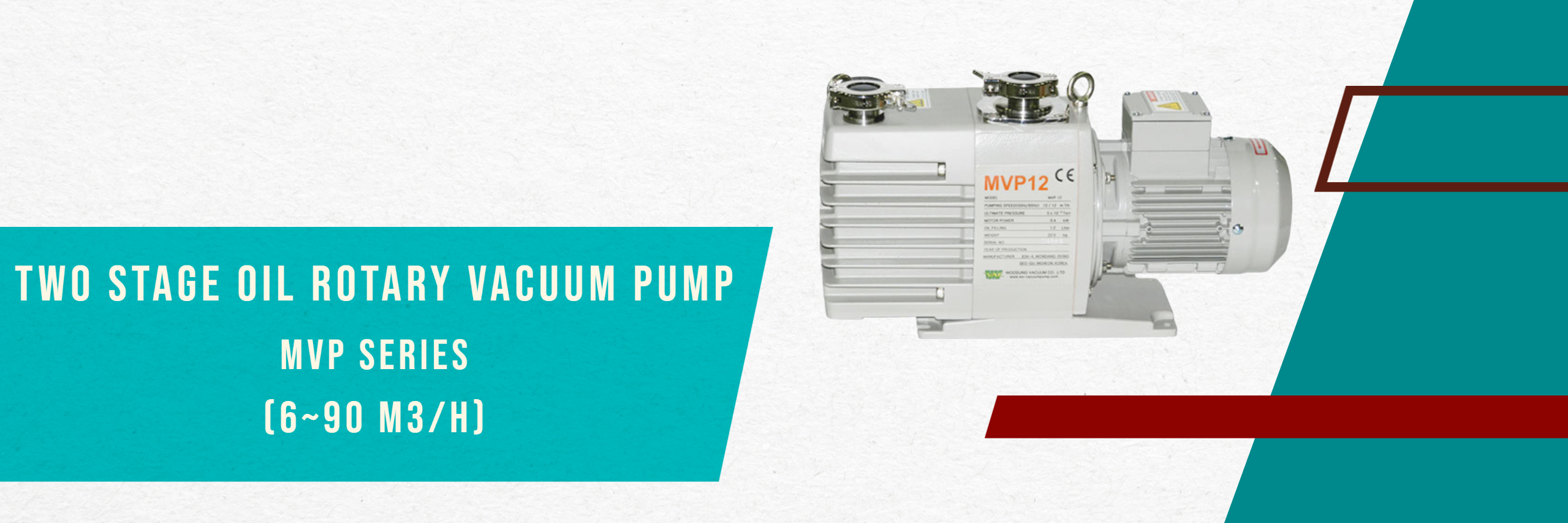

mvp vacuum pump

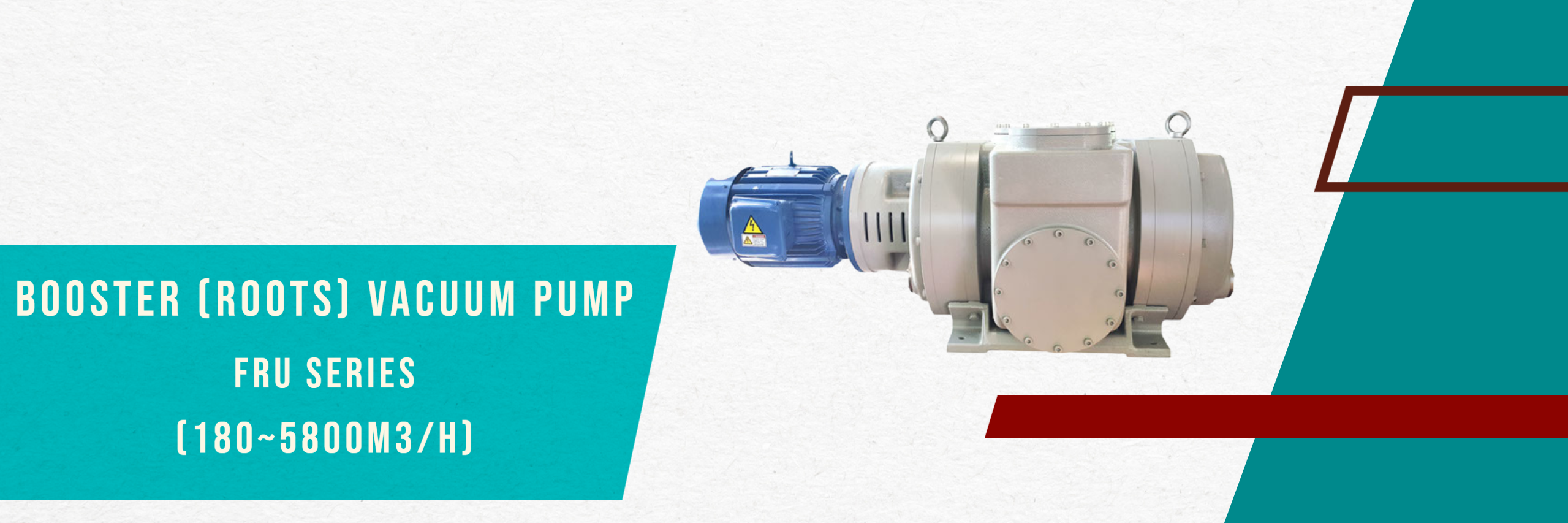

booster vacuum pump

What Is a Vacuum Pump?

A vacuum pump is a mechanical device that removes gas molecules from a sealed space to create a vacuum, meaning a space with pressure lower than atmospheric pressure. Vacuum pumps are essential in many scientific, industrial, and commercial processes where controlling air and gas pressure is necessary.

Vacuum pumps operate by drawing air or gas out of a closed chamber, either by compressing and moving the gas (positive displacement), accelerating and redirecting it (momentum transfer), or trapping and condensing it (entrapment). The result is a partial or complete vacuum that enables processes like vacuum drying, filtration, packaging, freeze drying, coating, and semiconductor manufacturing.

Types of Vacuum Pumps

There are several types of vacuum pumps, each designed for specific applications. Here are the most common categories:

Rotary Vane Vacuum Pump

- Oil-sealed or dry versions

- Widely used in labs and industry

- Compact, affordable, and reliable

- Suitable for medium to high vacuum applications

Diaphragm Vacuum Pump

- Oil-free operation

- Ideal for chemical and biological laboratories

- Resistant to corrosion and chemical vapors

- Low maintenance and quiet

Scroll Vacuum Pump

- Clean, dry, and efficient

- Excellent for cleanroom and analytical equipment

- Low vibration and oil-free

Piston Vacuum Pump

- Durable and capable of deeper vacuum levels

- Used in industrial and medical applications

- Can handle high workloads

Turbomolecular Vacuum Pump

- Used in high and ultra-high vacuum systems

- Common in research, semiconductor, and analytical fields

- Requires a backing pump

Roots (Blower) Vacuum Pump

- Often used as a booster pump with other types

- High pumping speed

- Used in metallurgy, chemical, and vacuum coating industries

Choosing the Right Vacuum Pump

The best vacuum pump depends on:

- Desired vacuum level (low, medium, high, or ultra-high)

- Type of gas or vapor to remove

- Application (e.g., drying, filtration, distillation, coating)

- Oil-free or oil-sealed preferences

Rotary Vane Vacuum Pump – Reliable, Compact & Powerful

A Rotary Vane Vacuum Pump is a positive displacement pump that is widely recognized for its efficiency, reliability, and versatility in both laboratory and industrial applications. It operates using a simple yet effective mechanism: a rotor with vanes is positioned inside a circular chamber. As the rotor spins, the vanes slide in and out, trapping air or gas and pushing it out through the exhaust. This action continuously removes air from the sealed system, creating a vacuum.

Rotary vane pumps are available in two main configurations:

- Oil-sealed rotary vane pumps, which use oil for sealing, cooling, and lubrication, allowing them to achieve lower pressures (better vacuum).

- Dry-running (oil-free) rotary vane pumps, which operate without oil, offering cleaner performance with less maintenance, ideal for applications where contamination is a concern.

How a Rotary Vane Pump Works

The rotor is mounted eccentrically inside a cylinder. As it turns, the vanes—usually made from carbon or composite material—are pushed outward by centrifugal force or springs, forming small chambers between them. As these chambers move around the pump body:

- The inlet port allows air/gas to enter.

- The volume decreases as the chamber rotates, compressing the gas.

- The compressed gas is expelled through the exhaust port.

This simple and continuous action enables steady vacuum generation with low noise and vibration.

Key Features of Rotary Vane Vacuum Pumps

- Oil-sealed mechanism for deeper vacuum levels

- Compact design – fits easily in labs or industrial setups

- Low noise and vibration during operation

- Continuous-duty performance – designed for long hours of operation

- Affordable and easy to maintain

Applications

Rotary vane pumps are commonly used in:

- Laboratories – vacuum filtration, drying, distillation, freeze drying

- Medical equipment – suction units, sterilizers

- Industrial processes – packaging, leak testing, forming, degassing

- HVAC and refrigeration – refrigerant recovery and evacuation

- Automotive – brake line vacuuming, fuel system testing

Oil-Sealed vs. Dry Rotary Vane Pumps

There are two main types:

- Oil-Sealed Rotary Vane Pumps

- Reach deeper vacuum levels

- Better for continuous use and industrial applications

- Dry Rotary Vane Pumps

- Oil-free, cleaner operation

- Suitable for clean environments like labs and medical use

Why Choose Biolabmarket?

- Wide range of rotary vane pumps in stock

- Expert guidance for choosing the right model

- Competitive prices and fast delivery

- Technical support and after-sales service

Here’s a general price range for different types of vacuum pumps. Keep in mind that prices vary depending on brand, capacity, vacuum level, oil-free/oil-sealed design, and region. These are estimated retail prices for standard models (not industrial-scale custom systems):

Estimated Prices for Vacuum Pumps

| Type of Vacuum Pump | Approximate Price Range (USD) | Notes |

| Rotary Vane Vacuum Pump | $300 – $3,000 | Oil-sealed models for labs/industry |

| Oil-Free Rotary Vane | $600 – $3,500 | Clean applications, more expensive |

| Diaphragm Vacuum Pump | $200 – $1,500 | Ideal for labs; oil-free & chemical resistant |

| Scroll Vacuum Pump | $2,000 – $10,000+ | Oil-free, quiet, for cleanroom or sensitive equipment |

| Piston Vacuum Pump | $500 – $3,000 | Durable, often used in industry or medical settings |

| Turbomolecular Vacuum Pump | $5,000 – $20,000+ | Ultra-high vacuum; used in R&D, semiconductor |

| Roots Blower Vacuum Pump | $1,500 – $10,000+ | Booster pump; used in metallurgy, coating |

| Liquid Ring Vacuum Pump | $2,000 – $15,000 | Used in chemical/petrochemical processes |

Wet and Dry Vacuum Pumps

Vacuum pumps can also be classified based on their lubrication and sealing methods, which fall into two main categories: wet-lubricated and dry-lubricated systems. This distinction significantly influences their operational characteristics such as durability, pumping efficiency, and risk of fluid contamination.

Wet Vacuum Pumps

Wet vacuum pumps typically utilize oil as the primary lubricating and sealing fluid, making them more affordable compared to dry vacuum pumps. The oil serves multiple purposes—it not only lubricates moving components but also assists in heat dissipation and filtration of contaminants. This oil is circulated through the system using an auxiliary lubrication circuit. However, a major drawback of wet pumps is the inevitable mixing of oil with the process gas. To address this, an oil separator is installed downstream to separate the oil from the exhaust gas before discharge.

Dry Vacuum Pumps

Dry vacuum pumps, on the other hand, operate without the use of conventional liquid lubricants. Instead, they rely on dry or solid lubricating materials such as graphite, PTFE (Teflon), or molybdenum disulfide. These substances possess a low coefficient of friction, which helps minimize direct metal-to-metal contact between moving parts. To manage heat generated during operation, water-cooled jackets are incorporated into the pump housing. The primary advantage of dry vacuum pumps lies in their clean, contamination-free operation, which makes them ideal for sensitive applications. Additionally, they generally require less frequent maintenance compared to wet systems.

Which Type of Vacuum Pump Has the Highest Vacuum Accuracy?

Among different types of vacuum pumps, the oil-sealed vacuum pump offers the highest level of accuracy in vacuum generation. Therefore, when very low levels of vacuum are required, this type of pump is the best choice. If there are no restrictions on the use of oil, it is highly recommended to use an oil-sealed vacuum pump.

What Is the Key Advantage of a Dry Vacuum Pump Compared to Other Types?

Dry vacuum pumps operate without the need for oil and are air-cooled. This makes them an ideal option for applications where strict hygienic standards must be maintained—such as in medical equipment, pharmaceutical industries, and food industries. In addition, long service life and lower maintenance costs are among the major advantages of dry vacuum pumps.

General Categories of Vacuum Pumps

In general, vacuum pumps are classified into three main categories:

Dry Vacuum Pump

Liquid Ring (Water) Vacuum Pump

Oil-Sealed Vacuum Pump

Common Questions

How are vacuum pumps classified based on their cooling method?

Vacuum pumps can be classified into several categories based on their cooling method.

In the first type, oil serves as the cooling agent, while in the subsequent types, air and water are used for cooling, respectively.

What is the lifespan of a vacuum pump?

The lifespan depends on various factors such as the type of pump, operating conditions, and level of maintenance. High-quality pumps typically last between 5 to 10 years or even longer, while lower-cost pumps may require replacement sooner.

How much noise does a vacuum pump produce?

The amount of noise produced by a vacuum pump depends on its type and model. Oil-sealed pumps generally operate more quietly, while dry and high-speed pumps may generate more noise. Using soundproof covers can help reduce the noise level.

What are the main applications of vacuum pumps?

Vacuum pumps are widely used across various industries due to their diverse performance and design. Some of the most important applications include:

Central suction systems in hospitals

Textile and weaving industries

Printing and packaging industries

Wood and MDF industries

Chemical and pharmaceutical industries

Mining and metal industries

Food industry