- sales@biolabmarket.com

- +1 (469) 819-5592

Introduction

In high-vacuum and ultra-high-vacuum (UHV) systems, the need for clean, efficient, and precise pumping solutions is paramount. Among the various types of vacuum pumps available, turbomolecular vacuum pumps (often abbreviated as TMPs or turbo pumps) stand out for their ability to handle low-pressure environments with extreme precision. These pumps are critical components in industries such as semiconductor manufacturing, surface analysis, space research, and more.

This comprehensive article explores how turbomolecular pumps work, their key features, applications, benefits, and how to select the right model for your vacuum system.

What is a Turbomolecular Vacuum Pump?

A turbomolecular vacuum pump is a high-vacuum pump that operates by transferring momentum to gas molecules through a series of fast-spinning rotors and stationary stators. It was first developed in the late 1950s to overcome the limitations of diffusion pumps, especially for applications requiring oil-free operation and high levels of cleanliness.

TMPs are capable of achieving pressures as low as 10⁻¹⁰ mbar, making them suitable for ultra-high-vacuum environments where conventional mechanical pumps cannot operate effectively.

What do turbomolecular pumps do?

At the core of a turbomolecular pump lies the principle of momentum transfer, where gas molecules are accelerated from the pump inlet toward the exhaust.

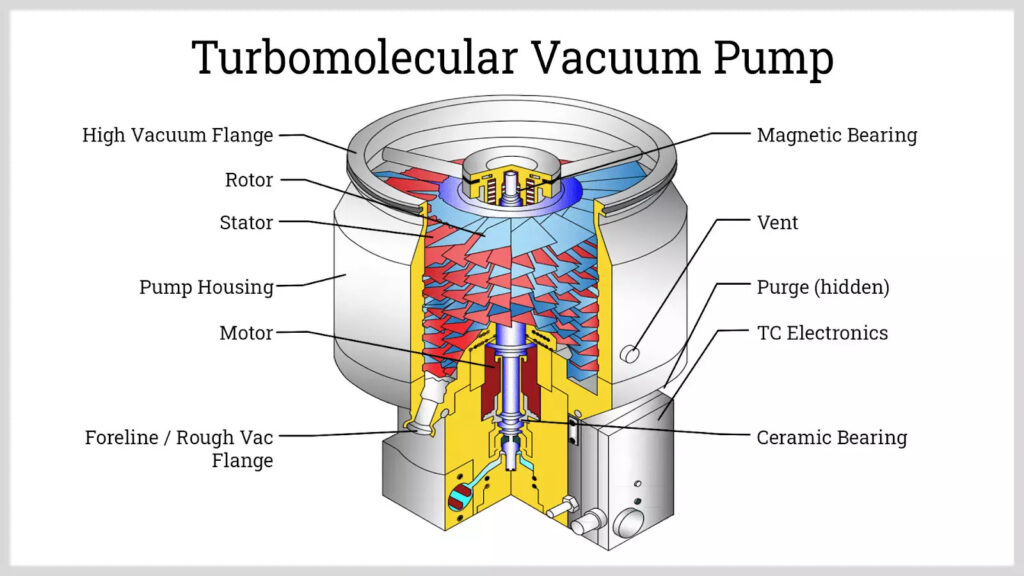

Key Components:

- Rotor Blades: Spin at extremely high speeds (typically 20,000–90,000 RPM).

- Stator Blades: Stationary vanes positioned between rotor stages that redirect the gas flow.

- Pump Housing: Contains the entire rotor-stator assembly.

- Bearing System: Usually either magnetic (for frictionless rotation) or hybrid (mechanical plus magnetic).

- Drive Electronics: Control the rotation and monitor performance parameters.

Process Overview:

- Gas enters the pump through the inlet flange.

- As molecules strike the rotating blades, they gain directional momentum toward the outlet.

- Stators help reorient the gas flow for the next rotor stage.

- This cycle repeats across multiple stages until the gas reaches the backing pressure level, at which point it’s expelled by a backing pump.

Note: A turbomolecular pump always needs a backing pump (such as a scroll or rotary vane pump) because it can’t pump at atmospheric pressure.

Turbomolecular Pump Advantages

Turbomolecular pumps offer numerous advantages, especially when operating in controlled, clean, or sensitive environments:

Oil-Free and Contamination-Free Operation

Since TMPs don’t use oil in the vacuum path, they eliminate the risk of oil backstreaming—a major concern in cleanroom and semiconductor environments.

Ultra-High Vacuum Capability

They can achieve base pressures lower than 10⁻⁹ mbar, which is essential for applications like electron microscopy, mass spectrometry, and surface science.

High Compression Ratios

Turbo pumps are particularly effective at compressing light gases such as hydrogen and helium, which are notoriously difficult to evacuate.

Low Vibration and Quiet Operation

Especially when equipped with magnetic bearings, these pumps produce minimal vibration, making them ideal for sensitive instruments.

Compact and Modular Design

Their relatively small footprint allows integration into various systems, including benchtop analytical instruments.

Common Applications of Turbomolecular Pumps

The high performance of turbomolecular vacuum pumps makes them indispensable across multiple high-tech industries. Here are some of the most prominent applications:

Semiconductor and Microelectronics

- Thin film deposition (PVD, CVD)

- Lithography systems

- Plasma etching

- Ion implantation

Analytical Instruments

- Mass spectrometers

- Electron microscopes (SEM, TEM)

- X-ray photoelectron spectroscopy (XPS)

- Residual gas analyzers

Vacuum Coating

- Optical lens coating

- Decorative and protective coatings

- Solar panel and display manufacturing

Space Simulation

- Creating ultra-high vacuum chambers that simulate the conditions of outer space

- Used in satellite and spacecraft testing environments

Research and Academia

- Particle accelerators

- Fusion reactors

- Nanotechnology and materials research

Pharmaceuticals and Biotechnology

- Freeze-drying (lyophilization)

- Sterile manufacturing

- Vacuum drying systems

Types of Turbomolecular Pumps

Depending on their design and intended use, turbo pumps can be categorized into different types:

Bearing Types

- Magnetic Bearing: Contactless, suitable for clean environments; reduced wear and longer lifespan.

- Hybrid Bearing: Combines mechanical bearings at the exhaust side with magnetic bearings at the high-vacuum side; cost-effective alternative.

Cooling Systems

- Air-Cooled: Simpler setup but less efficient for continuous operation.

- Water-Cooled: More effective heat dissipation; ideal for high-duty cycles.

- Drive Configuration

- Integrated Drive: More compact and easy to install.

- Remote Drive: Allows for placement in tight or vibration-sensitive systems.

Key Considerations for Selection

When choosing a turbomolecular vacuum pump, the following factors should be evaluated:

- Pumping Speed

Measured in liters per second (l/s), the required speed depends on the volume of your vacuum chamber and the desired pump-down time. - Compression Ratio

Especially important for light gases if your process involves hydrogen or helium. - Base Pressure

Ensure the pump can reach the required final vacuum level. - Back Pressure Tolerance

Check compatibility with the backing pump to avoid overloading. - Mounting Orientation

Some pumps are orientation-sensitive; verify if vertical or horizontal installation is required. - Vibration Sensitivity

For precision instruments, opt for models with magnetic bearings or integrated vibration damping. - Cost and Maintenance Requirements

Consider long-term operation costs, service intervals, and availability of spare parts.

Maintenance Tips

Turbomolecular pumps are designed to operate reliably for long periods, but preventive maintenance enhances performance and longevity:

- Keep Backing Pump Functional: Ensure it’s working properly to avoid backstreaming or overload.

- Use Proper Venting: Rapid venting can damage rotors; follow manufacturer guidelines.

- Avoid Particle Ingress: Use appropriate filters or screens to keep contaminants out.

- Monitor Bearings: If using hybrid bearings, replace worn components as specified.

- Log Operational Data: Temperature, rotor speed, and vibration logs help detect early signs of issues.

Leading Manufacturers

Some of the most respected turbomolecular vacuum pump manufacturers include:

- Pfeiffer Vacuum (Germany)

- Edwards Vacuum (UK)

- Leybold (Germany)

- Shimadzu (Japan)

- Agilent Technologies (USA)

- ULVAC (Japan)

These companies offer a broad range of turbo pump models tailored to different technical requirements, from small laboratory setups to large-scale industrial systems.

Final Thoughts

Turbomolecular vacuum pumps are the backbone of modern high-vacuum systems, combining speed, efficiency, and cleanliness in a compact design. Whether you’re working in nanotechnology, semiconductor fabrication, or deep space simulation, investing in the right turbo pump ensures reliable operation and minimal contamination risks.

Understanding how these pumps function, their strengths, and their application areas will empower engineers, researchers, and facility managers to make informed decisions that enhance system performance and reduce downtime.

Need help selecting the right turbomolecular pump for your system?

We can assist with product comparison, specifications, and sourcing from leading manufacturers. Just let us know your application requirements!

Related Products – Freeze Dryer

If you’re exploring advanced vacuum equipment like turbomolecular pumps, you may also be interested in freeze dryer. Freeze drying (lyophilization) is an essential process in many laboratory and industrial applications, allowing for the preservation of samples without compromising their structure or quality. To explore our full range of freeze dryers, click the link below:

What are the main advantages of turbomolecular pumps?

Turbomolecular pumps offer clean, oil-free operation, high pumping speeds, and the ability to reach ultra-high vacuum. They are ideal for sensitive applications like mass spectrometry, electron microscopy, and semiconductor manufacturing.

Do turbomolecular pumps require a backing pump?

Yes, turbomolecular pumps must be paired with a backing pump to maintain proper operation. The backing pump reduces the outlet pressure so the turbopump can efficiently compress and remove gas molecules.

What maintenance is required for turbomolecular vacuum pumps?

Turbomolecular pumps require minimal maintenance but should always be operated with a proper backing pump and clean system to avoid contamination. Regular checks of the backing pump and cooling system are essential to ensure long-term reliable performance.